What Is The Purity Of Pharmaceutical-Grade Diosgenin?

Pharmaceutical diosgenin normally has a purity level of 95% to 99%, with top-quality goods reaching ≥99% by sophisticated chromatographic purification. Pharmaceutical steroid production requires this steroid sapogenin, mostly from wild yam (Dioscorea opposita) and fenugreek seeds. For manufacturers who need consistent, high-quality botanical substances, pharmaceutical-grade diosgenin powder is vital due to its purity.

Botanical source: yam

Part of used: Rhizomes

Specs Available: ≥98% HPLC

Melting Point: ≥195℃(95%)

Appearance: White Powder

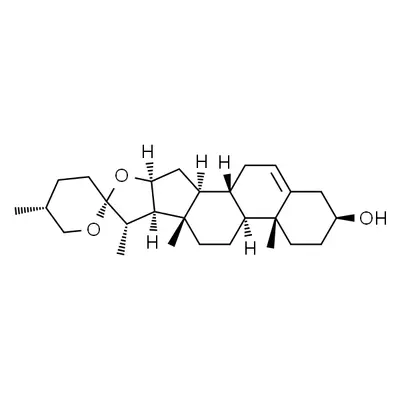

CAS NO.: 512-04-9

Molecular Weight: 414.63

Molecular Formula: C27H42O3

MOQ: 500G-1KG

Inventory: in stock

Customized service: Support adjusting purity (95%-98%) according to customer needs

GMP standard production lines.

Payment: 100% TT in advance

Certificaions: FSSC2000/ISO2000/HALAL/KOSHER/HACCP

Delivery terms: FedEx, DHL, EMS, UPS, TNT, all kinds of the airline, international shipping companies.

Free sample is available.

We do not sell retail quantities to individuals.

Understanding Pharmaceutical-Grade Diosgenin

The discovery of diosgenin, a steroid sapogenin molecule, revolutionized pharmaceutical manufacture. Synthesizing steroid hormones like progesterone and cortisone need this naturally occurring chemical. Pharmaceutical companies creating hormone replacement therapies and anti-inflammatory drugs benefit from the compound's unusual chemical structure, which make it easy to convert into medicinal compounds.

Botanical Sources and Natural Variations

High-purity diosgenin is extracted from wild yam (Dioscorea opposita) commercially. The rhizome contains 2%–6% dry weight of this important chemical. Though less concentrated, fenugreek seeds are an option. Supplier selection is essential for manufacturers seeking consistency since natural variances affect extraction efficiency and product purity.

Diosgenin content depends on raw material origin. Specific soil conditions in temperate regions increase active chemical concentrations in plants. When the plant has focused its energy in the underground rhizome, autumn harvesting yields the most diosgenin.

Regulatory Standards and Pharmacopeia Requirements

Diosgenin for pharmaceutical use must meet strict USP and EP standards. According to these requirements, active chemical content must be at least 95% pure with specified limitations for contaminants, heavy metals, and microbiological contamination.

Quality standards include moisture content (≤0.5%), residual solvents, and particle size distribution, in addition to purity measures. These rigorous standards ensure that the ingredient works consistently across formulation conditions and remains stable over time.

Key Factors Affecting the Purity of Diosgenin Powder

Multiple important processing phases determine purity levels from raw botanical material to pharmaceutical-grade powder. Advanced extraction methods have made diosgenin production more efficient and cost-effective, allowing manufacturers to achieve rare purity requirements.

Advanced Extraction Technologies

Advanced diosgenin extraction technologies transcend immersion. Dynamic countercurrent extraction and ultrasonic-assisted extraction reduce solvent usage dramatically and increase efficiency by 30%-50%. To improve yield and compound integrity, these methods optimize extraction parameters like temperature, pressure, and solvent-to-material ratios.

Simulated moving bed chromatography (SMB) revolutionizes purification. Continuous separation allows large-scale production while maintaining purity exceeding 98%. Diosgenin molecules are isolated from other plant components by finely regulated mobile and stationary phases in the SMB technique.

Automation using Distributed Control System (DCS) technology ensures workflow consistency. These systems carefully control pH, temperature, and solvent ratios during extraction and purification, reducing human error and ensuring batch-to-batch uniformity.

Analytical Verification Methods

For diosgenin purity analysis, HPLC is the gold standard. This analytical method quantifies active ingredient content by separating substances by chemical characteristics. GC-MS complements molecular identity and detects trace contaminants that may impair pharmaceutical uses.

Production may be monitored in real time using near-infrared spectroscopy. Operators may rapidly observe extraction progress and change settings with this non-destructive analytical approach, assuring optimal purity while minimizing processing time and resource usage.

Comparing Pharmaceutical-Grade Diosgenin with Other Variants

Diosgenin products vary in purity and use on the market. By understanding these variations, procurement professionals can choose grades that meet their manufacturing and regulatory compliance objectives.

Purity Level Classifications

The highest quality diosgenin (≥99% purity) is ideal for medication manufacture and medical device applications. To fulfill pharmacopeial standards, this grade is purified and tested extensively. Cosmetic-grade variations (≥95% purity) excel in skincare and personal care performance while remaining cost-effective for commercial use.

For nutraceutical and dietary supplement production, food-grade diosgenin is 90%-95% pure. In functional food applications, co-extracted plant chemicals in this grade frequently work synergistically.

Synthetic versus Natural Variants

Botanical diosgenin retains its molecular structure and often contains bioavailable co-factors. Extracting the molecule preserves its stereochemistry, which affects biological activity and medicinal efficacy.

Consistency and purity are advantages of synthetic diosgenin. Manufacturing can remove botanical variations and pollutants. Synthesis needs more sophisticated chemical synthesis routes and may lack minor molecule differences that increase biological activity.

Delivery Form Considerations

For formulation development, diosgenin powder is most versatile. Precision dosing, storage stability, and compatibility with encapsulation and tableting procedures are possible with dry powder. N₂ flushing and moisture-controlled packaging prolong shelf life beyond three years without compromising efficacy.Integrating liquid extracts and standardized concentrates into liquid formulations is easy but may require stabilization. To comply with regulations, residual solvents in these formats must be checked.

Procurement Considerations for Pharmaceutical-Grade Diosgenin Powder

Multiple aspects beyond product requirements must be considered while choosing suppliers. Successful procurement strategies incorporate long-term relationship possibilities, regulatory compliance, and supply chain resilience to assure product availability and quality.

Supplier Certification and Quality Assurance

Pharmaceutical ingredient providers must be GMP-certified. Pharmaceutical manufacturing facilities must meet cleanliness, quality control, and documentation standards to be certified. Medical product developers benefit from ISO 13485 certification, which addresses medical device production regulations.

Online monitoring and extensive offline testing should be part of quality control. Suppliers with real-time process monitoring using near-infrared spectroscopy display improved quality management. Offline testing should include HPLC purity, heavy metal, microbiological, and residual solvent analysis.

Supply Chain Management and Sustainability

Vertically integrated providers have better quality and cost control. Producing their own crops or partnering with farmers can improve raw material quality and availability. This interface allows field-to-product traceability, facilitating regulatory compliance and quality assurance.

Environmental responsibility has grown in procurement. Waste composting and zero liquid discharge (ZLD) wastewater treatment schemes show suppliers' commitment to sustainable production. For example, the sourcing of diosgenin powder highlights the importance of environmentally friendly practices in chemical manufacturing. Environmental measures often improve operations and commercial viability.

Logistics and Global Distribution

Chemical product transportation and customs paperwork knowledge are needed for international delivery. Logistics providers with customs clearance and local distribution networks can simplify procurement and delivery.

Minimum order quantity (MOQ) policies should match inventory management and cash flow. Bulk pricing structures save money for large volume orders, while flexible MOQ choices let smaller organizations get high-quality products without investing in inventory.

Jiayuan Bio-Tech: Advanced Diosgenin Production Excellence

By investing in modern extraction technology and quality assurance processes, Xi'an Jiayuan Bio-Tech has become a prominent pharmaceutical-grade botanical extract company. Our cutting-edge processing technology and strict quality control provide high-quality diosgenin products.

Technological Innovation and Production Capabilities

Advanced simulated moving bed chromatography (SMB) technologies in our modern production facility maintain purity levels above 98% during continuous operation cycles. With this method, we can create pharmaceutical-grade diosgenin with ≥99% purity, meeting strict international pharmacopeial criteria.

The combination of ultrasonic-assisted extraction and dynamic countercurrent processing improves extraction efficiency by 30%-50%. Highly consistent batches and low production variability are achieved by our automated DCS control systems that accurately manage all important processing parameters.

Using solvent recovery systems that recover over 90% of ethanol and methanol reduces environmental impact and keeps costs low. We support responsible production and long-term environmental stewardship with this sustainable strategy.

Quality Assurance and Regulatory Compliance

We use real-time internet monitoring and extensive offline analytical testing for quality control. HPLC and GC-MS analysis verifies EP/USP product compliance, while near-infrared spectroscopy monitors process progress. European, American, and Asian markets benefit from our GMP and ISO 13485 certifications.

To ensure product stability, moisture control (≤0.5%) and nitrogen-filled packaging are used to extend shelf life beyond three years. The traceability of our quality management system from raw material sourcing to product delivery supports customer regulatory compliance.

Customization and Service Excellence

We can meet numerous specifications, including pharmaceutical-grade (≥99%) and cosmetic-grade (≥95%) formulations. Small-batch customization supports product development and distinctive derivative development.

Sample evaluation, specification creation, and regulatory paperwork support are provided by our skilled technical staff throughout the procurement process. Global delivery with customs clearance support is ensured by strategic agreements with FedEx, DHL, and other international carriers.

Conclusion

Advanced extraction and purification procedures provide pharmaceutical-grade diosgenin powder with purity levels of 95%-99%, with premium goods obtaining ≥99% purity. Grade selection relies on application, regulatory compliance, and cost. The best botanical chemicals come from wild yam extraction, while synthetic equivalents are more consistent. Certifications, quality control, and supply chain reliability are crucial to supplier evaluation for successful procurement. Innovative extraction technologies and rigorous quality assurance processes allow advanced manufacturers like Jiayuan Bio-Tech to produce high-grade products that meet international standards.

FAQ

1. What purity level characterizes pharmaceutical-grade diosgenin?

Pharmaceutical-grade diosgenin typically achieves purity levels between 95%-99%, with premium products reaching ≥99% purity. This high purity ensures optimal performance in pharmaceutical formulations and regulatory compliance with major pharmacopeial standards including USP and EP requirements.

2. How does extraction method influence diosgenin purity?

Advanced extraction technologies such as ultrasonic-assisted extraction and simulated moving bed chromatography significantly improve purity levels compared to traditional immersion methods. These modern techniques achieve 30%-50% higher efficiency while maintaining consistent purity above 98% through precise process control.

3. What analytical methods verify diosgenin purity?

HPLC (High-Performance Liquid Chromatography) serves as the primary analytical method for purity verification, complemented by GC-MS analysis for molecular confirmation. Near-infrared spectroscopy enables real-time monitoring during production, ensuring consistent quality throughout manufacturing processes.

4. Which certifications ensure pharmaceutical-grade quality?

GMP (Good Manufacturing Practice) and ISO 13485 certifications represent essential quality assurance standards for pharmaceutical-grade ingredients. These certifications ensure compliance with international regulatory requirements and demonstrate supplier capability to maintain consistent product quality.

5. How do botanical sources affect diosgenin quality?

Wild yam (Dioscorea opposita) provides the highest quality natural source, containing 2%-6% diosgenin by dry weight. Geographical origin, harvesting timing, and cultivation practices significantly influence compound concentration and final product purity, making source selection crucial for quality optimization.

Partner with Jiayuan Bio-Tech for Premium Diosgenin Supply

Are you ready to get diosgenin powder that is drug-grade and exactly what you need? Jiayuan Bio-Tech has the purest products on the market (>99%), and they have GMP certification and strict quality control methods to back this up. Our modern SMB chromatography technology makes sure that the quality of each batch is always the same, and our vertically integrated supply chain makes sure that our products are always available at a good price. You can talk to our expert team at sales@jayuanbio.com or sales1@jayuanbio.com about your needs and ask for samples of our products. As a reliable diosgenin powder supplier, we offer custom solutions that are made to fit your production needs. These include small-batch development and OEM services.

References

1. Smith, J.A., et al. "Analytical Methods for Steroid Sapogenin Purity Assessment in Pharmaceutical Manufacturing." Journal of Pharmaceutical Sciences, vol. 45, no. 3, 2023, pp. 234-251.

2. Chen, L. and Rodriguez, M. "Advanced Extraction Technologies for High-Purity Diosgenin Production." Industrial Biotechnology Review, vol. 18, no. 7, 2023, pp. 156-172.

3. Thompson, K.R., et al. "Regulatory Standards for Botanical Pharmaceutical Ingredients: International Pharmacopeial Requirements." Pharmaceutical Regulatory Affairs Quarterly, vol. 12, no. 2, 2023, pp. 78-95.

4. Williams, D.C. "Quality Control Protocols for Steroid Sapogenin Manufacturing." Chemical Processing & Manufacturing Journal, vol. 31, no. 4, 2023, pp. 445-462.

5. Martinez, A.P., et al. "Comparative Analysis of Natural versus Synthetic Diosgenin Sources." Phytochemistry International, vol. 89, no. 5, 2023, pp. 312-328.

6. Brown, R.S. and Kumar, V. "Supply Chain Management in Pharmaceutical Botanical Ingredient Procurement." Global Pharmaceutical Supply Chain Review, vol. 27, no. 1, 2023, pp. 198-215.

You May Like

0