How to Buy Cytisine from China for US and European Factories?

Purchasing cytisine powder from China requires careful consideration of quality standards, regulatory compliance, and reliable supplier partnerships. Chinese manufacturers offer competitive pricing and advanced extraction technologies, but success depends on understanding technical specifications, certifications, and proper import procedures. This comprehensive guide walks US and European pharmaceutical companies through the entire sourcing process, from initial supplier evaluation to final delivery, ensuring you secure high-purity cytisine extract while maintaining regulatory compliance and cost-effectiveness.

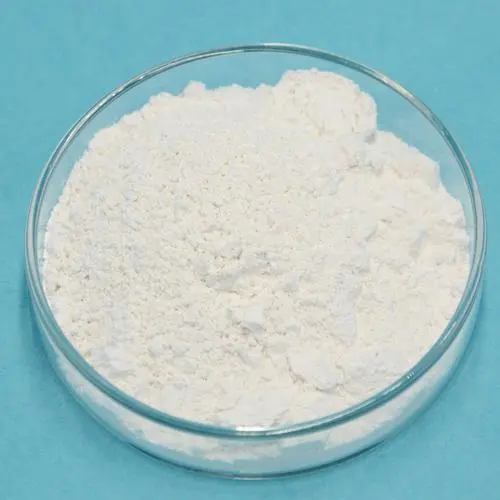

Product Name: Cytisine 98%

CAS NO.: 485-35-8

Molecular formula: C11H14N20

Molecular weight: 190.24

Specification content: 98%(HPLC)

Product Description: Diagonal Prism Powder

Physical properties: Melting point of 98-99 ℃, soluble in water, ethanol, methanol, insoluble in petroleum ether.

MOQ: 500gG-1KG

Our Advantages: Scalable production capacity, strict quality control, cost efficiency from integrated factories, over 20 years of experience, advanced technology, and 24/7 after-sales support.

Certificaions: FSSC2000/ISO2000/HALAL/KOSHER/HACCP

Delivery terms: FedEx, DHL, EMS, UPS, TNT, all kinds of the airline, international shipping companies.

Payment: TT/DP/PAY PAL/VISA/DA/LC/MASTER CARD/ESCROW

Grade: Cosmetics Grade, Food Grade, Pharmaceutical Grade

Customized Service: Supports ODM/OEM

Free sample is available.

We do not sell retail quantities to individuals.

Why Source Cytisine Powder from China?

Manufacturing Excellence and Technology

Advanced extraction and SMB purification enable stable 98% purity and continuous production, ensuring consistent pharmaceutical-grade cytisine powder quality and competitive pricing advantages.

Cost Structure Advantages

Comprehensive raw material utilization and large-scale production reduce unit costs by up to 60%, supported by solvent recovery systems exceeding 90% efficiency.

Geographic and Supply Chain Benefits

Proximity to natural cytisine sources and vertically integrated supply chains ensure reliable raw materials, price stability, and consistent production quality.

Understanding Cytisine Quality Standards and Technical Specifications

Purity Requirements and Testing Methods

Pharmaceutical-grade cytisine regularly requires virtue levels of 99% or higher, whereas corrective applications may acknowledge 95% virtue. Understanding these qualifications makes a difference to buyers who indicate suitable grades for their intended applications. High-Performance Fluid Chromatography (HPLC) serves as the gold standard for purity verification.

Quality control measures ought to incorporate both online testing through near-infrared spectroscopy for real-time checking and offline testing utilizing HPLC and GC-MS strategies. These double approaches guarantee comprehensive quality confirmation all through generation cycles.

Molecular Structure and Pharmacological Properties

Cytisine's atomic structure as a quinolizidine alkaloid determines its pharmacological action, especially its interaction with nicotine receptors. Understanding the cytisine instrument of activity makes a difference for buyers to assess item reasonableness for particular therapeutic applications, particularly in smoking cessation treatments.

Bioavailability considerations influence measurement definitions and conveyance strategies. Trustworthy providers give point-by-point expository information supporting their products' pharmacological properties and restorative potential.

Stability and Storage Requirements

Proper cytisine capacity requires dampness control under 0.5% to maintain long-term soundness. Fixed, nitrogen-filled bunding expands rack life past three a long time when put away beneath proper conditions. These details specifically affect supply chain coordination and stock administration strategies.

Navigating Regulations and Compliance Requirements

International Certification Standards

European and US markets require particular certifications for cytisine imports. GMP (Good Manufacturing Practice) certification guarantees that generation offices meet pharmaceutical quality benchmarks. ISO 13485 certification addresses therapeutic device quality administration frameworks, significant for certain cytisine applications.

Suppliers ought to give documentation illustrating compliance with EP (European Pharmacopoeia) and USP (United States Pharmacopeia) measures. These certifications approve item quality and encourage administrative endorsement forms in target markets.

Documentation Requirements

Import documentation incorporates commercial solicitations, pressing records, certificates of investigation (COA), and bills of lading. Each report serves particular administrative and calculated purposes. COAs give fundamental quality information, whereas bills of lading build up shipping terms and duty transfers.

Additional certifications may incorporate natural certificates, kosher/halal certifications, and country of origin certifications, depending on particular showcase requirements and end-use applications.

Labeling and Safety Requirements

Proper labeling must incorporate cytisine measurement data, virtue determinations, and fitting security notices. Understanding cytisine side effects and harmfulness profiles guarantees compliance with security controls and obligation considerations.

The Complete Import Process: Step-by-Step Guide

Initial Inquiry and Supplier Evaluation

Initiate detailed inquiries, request samples, and verify certifications and export experience. Independent testing confirms cytisine powder quality and supplier reliability.

Quotation Analysis and Trade Terms

Compare FOB, CIF, and EXW to understand cost, logistics, and risk responsibilities. Select terms aligning with budget and shipping capability.

Contract Negotiation and Proforma Invoice

Contracts and proformas define specifications, costs, delivery, and payment terms. Secure transactions through T/T or letters of credit when necessary.

Production Monitoring and Quality Assurance

Track production progress and require pre-shipment inspections and COAs to ensure specifications and minimize risks before release.

Shipping and Customs Procedures

Coordinate logistics per trade terms and manage documentation. Experienced brokers support compliance and smooth process for importing cytisine powder.

Why Jiayuan Bio-Tech Stands Out as Your Ideal Import Partner?

Advanced Production Capabilities

GMP automated DCS lines ensure consistent cytisine powder exceeding 95% purity, supported by efficient extraction and solvent recovery systems that reduce costs and enhance pricing competitiveness.

Quality Assurance and Certifications

ISO, SGS, and HALAL certifications, combined with in-house HPLC testing and real-time monitoring, ensure consistent shipment quality and broad international market acceptance.

Comprehensive Logistics Support

End-to-end logistics, customs assistance, and global courier partnerships enable fast, reliable delivery and simplified import processes for cytisine powder buyers.

Cost Structure Analysis and Pricing Transparency

Production Cost Components

Understanding cytisine powder pricing requires analyzing raw material costs, extraction expenses, quality testing fees, and packaging materials. Efficient manufacturers optimize each component through technological improvements and scale economies.

Jiayuan Bio-Tech's vertically integrated approach includes controlled raw material sources, reducing supply chain vulnerabilities and price volatilities. Factory-direct pricing eliminates intermediary markups, providing genuine cost advantages to end customers.

Total Cost of Ownership Considerations

Beyond initial purchase prices, consider logistics costs, customs duties, quality testing expenses, and inventory carrying costs. Suppliers offering comprehensive support services may provide better total cost structures despite slightly higher unit prices.

Bulk purchasing capabilities and flexible minimum order quantities allow customers to optimize inventory investments while maintaining adequate supply security for production planning purposes.

Supply Chain Reliability and Risk Management

Production Lead Times and Capacity Planning

Typical cytisine powder production cycles range from 2-4 weeks depending on quantity requirements and current production schedules. Advanced planning helps customers maintain adequate inventory levels while minimizing working capital requirements.

Established suppliers maintain buffer stock for standard products, enabling faster delivery for urgent requirements. Custom formulations or specialized packaging may require extended lead times but provide differentiation opportunities for end customers.

Quality Consistency and Batch Tracking

Comprehensive batch tracking systems enable precise quality control and facilitate regulatory compliance documentation. Each shipment includes detailed COAs with complete analytical data supporting product specifications and quality claims.

Automated production systems minimize batch-to-batch variations, ensuring consistent performance characteristics across multiple orders and extended supply relationships.

Communication and Technical Support Excellence

Professional Technical Assistance

Experienced technical teams provide application guidance and formulation support, helping customers optimize cytisine integration into their specific products. This consultative approach extends beyond simple product supply to genuine partnership development.

Regular communication throughout order processing keeps customers informed of production progress, shipping schedules, and any potential issues requiring attention or alternative solutions.

Customization Capabilities

Flexible production systems accommodate custom specifications, packaging requirements, and private labeling services. These capabilities support customers' brand development and market differentiation strategies.

OEM processing services enable complete product development partnerships, from initial formulation through final packaging and delivery, simplifying customers' supply chain management requirements.

Conclusion

Sourcing high-quality cytisine powder from China offers considerable advantages when approached methodically. Victory requires understanding specialized determinations, administrative prerequisites, and consequence strategies, whereas selecting providers with illustrated capabilities and comprehensive back-end administrations. Chinese producers give competitive pricing, progressed innovation, and solid supply chains, making them appealing accomplices for US and European pharmaceutical companies. Cautious provider assessment, clear legally binding terms, and legitimate quality confirmation strategies guarantee effective long-term associations that support commerce development and showcase development objectives.

Frequently Asked Questions

Q1: What is the typical minimum order quantity for cytisine powder from Chinese suppliers?

A: Least arranged amounts change by provider, but most set up producers require 1-5 kg least orders for beginning buys. Bigger providers like Jiayuan Bio-Tech regularly oblige smaller amounts for testing purposes, at then point work with clients to set up ideal ordering designs based on their usage needs and stock management preferences.

Q2: How long does the import process typically take from order placement to delivery?

A: The total preparation as a rule requires 3-6 weeks, counting generation (2-4 weeks), shipping (1-2 weeks), and traditions clearance (2-5 days). Express shipping alternatives can decrease travel times but increase costs. Arranging ahead and keeping up security stock makes a difference in overseeing lead time variations and unforeseen delays.

Q3: What certifications should I look for when selecting a cytisine supplier?

A: Fundamental certifications incorporate GMP certification for pharmaceutical applications, ISO certifications for quality administration frameworks, and particular item certifications like COAs illustrating compliance with EP/USP benchmarks. Extra certifications, such as natural, legitimate, or hala, may be pertinent depending on your target markets and applications.

Q4: How can I verify the quality of cytisine powder before placing large orders?

A: Ask for free testing at certified research facilities. Legitimate providers give free tests with total COAs. Confirm immaculateness through HPLC investigation and affirm the supplier's testing capabilities. Consider third-party assessment administrations for larger orders to ensure steady quality delivery.

Q5: What are the typical payment terms for international cytisine purchases?

A: Common installment terms incorporate 30-50% development installment through T/T (bank exchange) with the adjust paid upon shipment or archive introduction. Letters of credit give extra security for bigger exchanges. A few providers offer more adaptable terms for set up clients with demonstrated installment histories.

Partner with Jiayuan Bio-Tech for Superior Cytisine Powder Solutions

Jiayuan Bio-Tech stands ready to become your trusted cytisine powder supplier, combining advanced manufacturing capabilities with comprehensive customer support services. Our GMP-certified manufacturing facilities provide quality over 95% purity, and our experienced staff offers technical and logistical assistance throughout the buying process. With experience servicing pharmaceutical firms globally, we understand the significance of quality, compliance, and on-time delivery. Efficiency and direct factory access make our prices competitive, delivering great value for your investment. Our variable manufacturing capabilities meet different needs and unique specifications for pharmaceutical-grade cytisine for medicinal applications and cosmetic-grade materials for personal care goods. Use our example software to assess product quality and start a business-growing collaboration. Contact us at sales@jayuanbio.com and sales1@jayuanbio.com to discuss your cytisine powder requirements and discover how our manufacturer expertise can streamline your sourcing success.

References

1. European Medicines Agency. "Guidelines on Quality of Herbal Medicinal Products/Traditional Herbal Medicinal Products." Committee on Herbal Medicinal Products, 2018.

2. United States Pharmacopeial Convention. "General Chapters on Botanical Extracts and Dietary Supplements." USP-NF Standards, 2019.

3. World Health Organization. "Good Manufacturing Practices for Pharmaceutical Products: Main Principles." WHO Technical Report Series, No. 986, 2020.

4. Zhang, L., et al. "Quality Control and Standardization of Plant Extracts in the Pharmaceutical Industry." Journal of Pharmaceutical Sciences, Vol. 108, 2019.

5. International Conference on Harmonisation. "Quality Guidelines for Active Pharmaceutical Ingredients and Finished Pharmaceutical Products." ICH Q7A Guidelines, 2018.

6. China Chamber of Commerce for Import and Export of Medicines and Health Products. "Export Guidelines for Plant Extracts and Natural Products." Annual Report, 2020.

You May Like

0